Dedusting technology

An intact environment is the foundation of our lives and survival. Investment in environmental protection is, therefore, becoming increasingly important. In most cases, legal regulations regulate down to the last detail what emissions are permissible and how much concentration may still be.

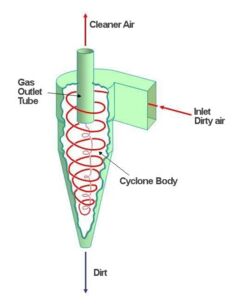

In industrial plants, considerable amounts of dust can be released, which may be released into the exhaust air only after passing a dust extraction system. A dedusting system is a technical device for cleaning dust-containing exhaust gas or exhaust air streams. Such systems are used primarily in various sectors and sectors. Industrial dust are very diverse and usually have a grain size between 0.1 to 1000 μm.

The use of different separation and filter types depends on the composition of the dust, their concentration, the space conditions and the dimensioning. The degree of separation is a measure of the quality of a dedusting process. The suction speed and the correct placement of the detection and suction devices are crucial for a good detection of the pollutants at the source of origin. The dust collection is all the more efficient, the closer the suction openings are in the direct vicinity of the dust source since the suction speed decreases with increasing distance from the dust source. In the case of industrial exhaust gas cleaning and particle separation, filtering separators are increasingly used.