Rotary feeders

We offer different types of air locks, feeders, valves, and individual solutions. Please click on the arrows ![]() in the listing to open or close the details.

in the listing to open or close the details.

Light metal-to-metal sealing feeders PSL

PSL feeders are metal-to-metal sealing feeders for charging and discharging operations in a dryer and sifter area.

The feeder consists of a stator (housing), rotor with inclined blades, 2 bearing caps on one side and a bearing arrangement on the other, and is directly driven by a bevel-geared motor.

The stator has not been provided with a wear-resistant protective coating, but the rotor blades are armour-plated.

Method of operation:

The chips are fed down an inclined chute into the path of the spinning rotor via cyclones, filters, or mechanical conveyors. In the upper section of the feeder, a bevel-ground cutter takes off any splinters raised by the turning motion of the rotor.

The feeder is not equipped with a bottom cutter.

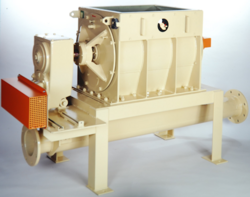

Rotary valve with knife PHD

PHD feeders are metal-to-metal sealing feeders for use in pneumatic medium-pressure conveyor systems at pressures of up to approx. 500 mbar.

The feeder consists of a stator (housing), rotor with shaft, caps with bearing units, support, feed injector, and drive assembly including block gearing, drive motor, and v-belt with protective casing.

The stator has been provided with a wear-resistant protective metal coating by means of metal spraying. The rotor blades are armour-plated.

Method of operation:

The chips are fed down an inclined chute into the path of the spinning rotor via cyclones, filters, or mechanical conveyors. In the upper section of the feeder, a bevel-ground cutter takes off any splinters raised by the turning motion of the rotor. A cutter in the lower section of the feeder serves as a stripper.

The turning motion of the rotor forces the material through the bottom-mounted injector into the conveyor pipe.

The type designation PHD 210 = 210m³/h at a 55% filling level.

Rotary valve with elastic sealing strips PZR

Rotary valves with elastic sealing strips are used to ensure as close as possible airtight and pressure-tight sealing underneath cyclones or filters. The rotary valves consist of a stator and a rotor. The rotor has a certain number of blades, which then form so-called chambers. The chambers are filled from above with bulk material such as dust or chips and then emptied downwards.

A filling level of 30 - 50% is recommended.

The rotary valves are driven by a geared motor via chain drive. A total of 18 sizes are available so that large flow ranges can be covered.

Areas of application include the wood-based materials industry, the paper industry, and the chemical industry.

Coarse air lock with moveable wall PKS

Air locks of the type PKS are preferably used on shovel dryers for discharging coarse particles and stones.

Technical structure:

The rotor of the sluice has a distance of 3 mm from the stator wall. After a stone or coarse material enters the sluice, a so-called evasive wall is pushed away via plate springs. The material can thus, be ejected without jamming.